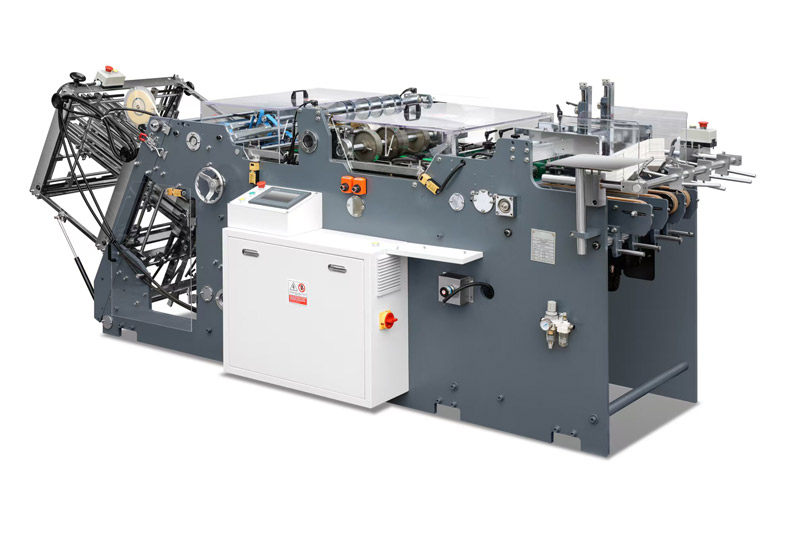

Carton Erecting Machine (Hamburger Box Machine) is a specialized forming machine capable of producing hamburger boxes, square boxes, food containers (for takeaways), fries boxes, and other types of paper boxes made from cardboard and corrugated paper.

1.Compact Frame and Stable Operation: The hamburger box machine boasts a compact frame with sturdy construction, ensuring stable operation and minimal noise.

2.Efficient and Stable Paper Feed: The paper feed section is controlled by an independent servo motor, providing high-efficiency and stable paper feeding.

3.High Operational Safety: The machine is equipped with a safety door, enhancing operational safety.

4.Quick and Easy Mold Change: Mold changing is simple and requires a short amount of time.

5.PLC Control: PLC control allows for the easy formation of complex box shapes.

6.Automatic Collection, Storage, and Counting: The machine features automatic collection, storage, and counting functions.

7.User-friendly Switch Design: The machine's switches are designed for safety and ease of operation.

|

Model: |

AHB-800 high speed box erecting machine (Hamburger box making machine) |

|||

|

Speed: |

Max 180 Pcs/min |

|||

|

Glue: |

Water based glue |

|||

|

Application material: |

150~600g/m2 cardboard and coated paper |

|||

|

Thickness: |

Max 1.5mm |

|||

| Paper size: | L=: 60~450mm W=: 60~580mm H=: 10~200mm Angle: 50~300 |

|||

|

Power: |

4.5KW |

|||

|

Power supply: |

Three phases, 380V, 50/60Hz, |

|||

|

Dimension (L*W*H): |

3520*1510*1420mm |

Packing dimension |

3550*1550*1700 mm |

|

|

Weight: |

2000KG; |

|||

|

Air consumption: |

Pressure: 6bar (0.6MPa); Air flow: 200 L/minute ; (0.2~0.4 m3/minute); Air compressor prepared by customer. |

|||

|

Customize molds. |

||||

|

4-corner box without cover, Boat Shape Box, Boat Tray, |

Max. 180pcs/min; |

|

Fries box (chips box, chips tray): |

Max. 140pcs/min |

|

Burger box, hot-dog box, Lunch box |

Max. 120pcs/min |

|

Food pail (DEEP food box): |

Max. 100pcs/min |

Attention: Speed will be affected by the box shape, size, thickness of paper, if the material is double side coated paper or tinfoil, an extra hot melting glue system is needed.

|

Item |

Model |

QTY |

Brand |

|

PLC controller |

DVP32ES200T |

1 PCS |

Siemens |

|

Touch screen |

DOP-B07S410 |

1 PCS |

|

|

Invertor |

M3.7KW |

1 PCS |

|

|

Servo motor for feeding |

1.5KW |

1PCS |

Innovance |

|

Relay |

24v |

8PCS |

Schneider |

|

Air switch |

2P-C25 |

1PCS |

|

|

Contactor |

LC1E1210 |

1PCS |

|

|

Contactor |

LC1E0910 |

1PCS |

|

|

Thermal relay |

LRE08N |

1PCS |

|

|

Encoder |

360P |

1PCS |

OMRON |

|

Gluing mort (DC) |

90 W |

1 PCS |

OBG motor |

|

Photoelectric switch |

XC-421 |

1 PCS |

Panasonic |

|

Sequential protector |

XJ3-G |

1PCS |

CHINT |

|

Main motor |

3 KW |

1 PCS |

Siemens |

|

Safe switch |

AZD |

4 PCS |

SHINOZAKI |

|

switch power supply |

NES |

1 PCS |

MEAN WELL |

|

Button |

XB2 |

5 PCS |

tend |

|

Emergency stop button |

XB2 |

3 PCS |

|

|

Button box |

TN2 |

2 PCS |

|

High stability, Hi Accuracy |

||

|

Main part |

Process |

Material |

|

Transmission Shaft |

CNC Lathe 1 rough grinding 1 surface treatment 2 finish grinding |

Chromium 12 Alloy Steel Tempering Process

|

|

Transmission Mechanism |

Internal Steel Wire Full Connection Type |

Timing belt, chain |

|

Feed inlet |

Cam and suction device |

|

|

Fastener |

12.9-grade Fastener |

|

|

Machine Frame |

Grinding Machine and Polishing Surface Treatment |

A3 Material or Parallel Key Type |

|

High safety |

||

|

Human friendly design, with all switches and buttons within a 0.6m radius of the operator |

||

|

A safety door is installed on the protective cover, and the equipment will automatically shut down once the protective cover is opened. |

||

GET A QUOTE