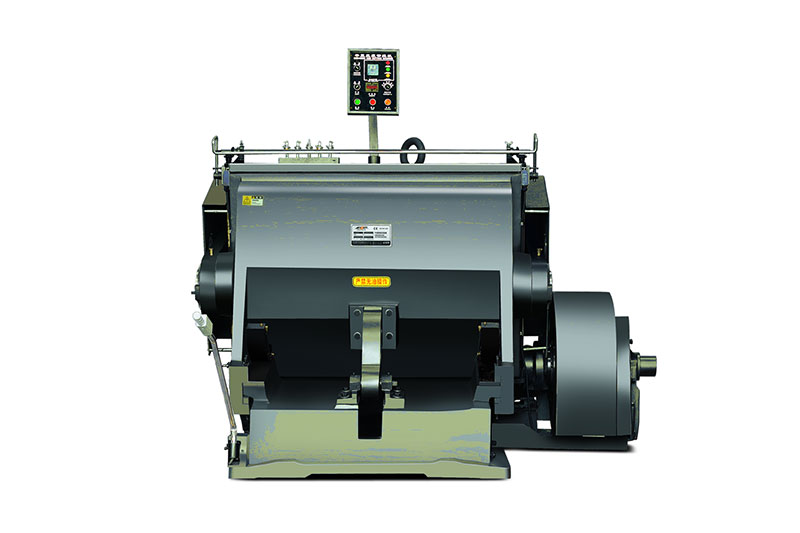

A flatbed die cutter is a machine used for cutting various materials into specific shapes. Here's how it generally works:

Die Preparation: A cutting die is selected or custom - made according to the desired shape of the cut. The die is usually a thin, metal plate with sharp edges that are shaped to match the pattern to be cut. For example, if you want to cut out circular shapes for making coasters, the die will have circular blades.

Material Placement: The material to be cut, such as cardboard, paper, plastic sheets, or leather, is placed on the flatbed of the die - cutter. The flatbed provides a stable and flat surface to support the material during the cutting process.

Upper and Lower Platen Movement: The die - cutter has an upper platen and a lower platen. The cutting die is attached to the lower platen. When the machine is activated, the upper platen comes down with a significant amount of force. This force presses the material against the cutting die on the lower platen.

Shearing Action: As the upper platen presses the material onto the die, the sharp edges of the die cut through the material. The pressure exerted is carefully calibrated to ensure a clean and accurate cut. The shearing action is similar to using a pair of very sharp scissors, but instead of two blades moving past each other, the material is forced against a stationary, sharp - edged die.

Cut - out Removal: After the cutting is complete, the cut - out shapes are either manually removed or, in some more advanced machines, there are mechanisms to eject the cut pieces automatically. For example, in a high - speed production setup, air jets may be used to blow away the cut - out pieces from the die and the remaining material.

Clean - up and Next Cycle: The leftover material (the waste) is removed from the flatbed, and a new sheet of material can be placed to start the next cutting cycle. The die may also be checked for any debris or damage to ensure the quality of subsequent cuts.

Overall, flatbed die cutters are an efficient way to produce large quantities of precisely - cut shapes for a wide range of industries including packaging, printing, and crafts.

GET A QUOTE