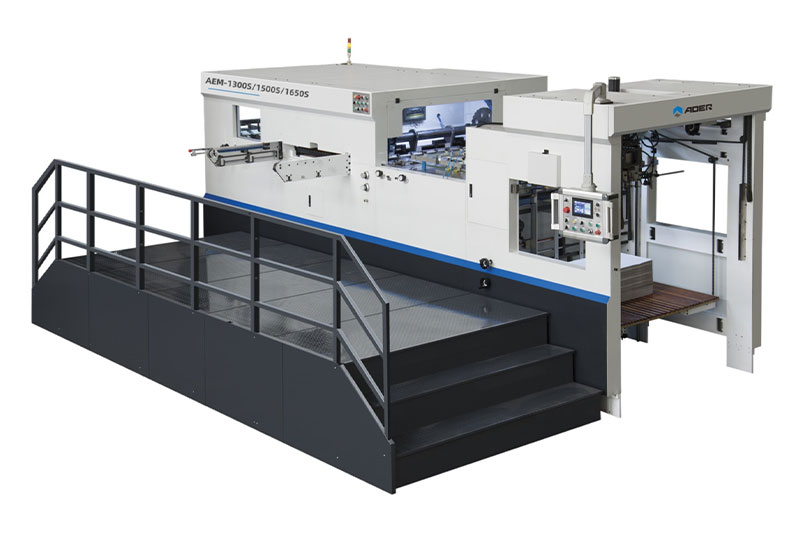

An automatic cutting machine is a piece of equipment that uses advanced technology to cut various materials with minimal human intervention.

Fabric Cutting Machines:

These are widely used in the textile and garment industry. They can precisely cut fabric according to pre - programmed patterns. For example, in a clothing factory, an automatic fabric cutting machine can cut multiple layers of fabric for shirt or trouser components. The machine uses a computer - aided design (CAD) system to translate the pattern into cutting instructions. It can handle different types of fabrics such as cotton, silk, and polyester, and can cut complex shapes like sleeves, collars, and pant legs.

Metal Cutting Machines:

Plasma cutting machines are a type of automatic metal - cutting equipment. They use a high - temperature plasma arc to melt and blow away the metal. This is useful for cutting thick metal sheets or plates. For example, in the construction of metal structures like bridges or in the manufacturing of heavy machinery, plasma cutting machines can cut steel components to the required sizes and shapes. Another example is laser cutting machines, which use a highly focused laser beam to cut through metal. The laser beam melts, burns, or vaporizes the metal, leaving a precise cut. Laser cutting is often used for cutting intricate designs in thinner metal sheets, such as in the production of jewelry or electronic enclosures.

Plastic Cutting Machines:

For cutting plastic materials, there are hot - wire cutting machines. These machines use a heated wire to cut through plastic. The wire melts the plastic as it passes through, creating a clean cut. They are commonly used in the production of plastic products like packaging trays, signs, and model - making components.

Programming and Control:

Automatic cutting machines are usually controlled by a computer - based system. Operators input the cutting patterns, dimensions, and other parameters into the machine's software. The software then converts these instructions into commands that the cutting mechanism can understand. For example, in a CNC (Computer Numerical Control) cutting machine, the software controls the movement of the cutting tool along the X, Y, and Z axes to achieve the desired shape.

Sensing and Feedback:

Many automatic cutting machines are equipped with sensors. These sensors can detect the position of the material, the thickness of the material, and the status of the cutting tool. For example, a sensor might detect if the cutting blade is getting dull and send a signal to the machine's control system to adjust the cutting speed or prompt the operator to replace the blade. Some machines also have vision - based sensors that can compare the actual cut with the programmed pattern and make real - time adjustments to correct any deviations.

Precision: They can achieve a high level of precision, often with tolerances as small as a fraction of a millimeter. This is crucial in industries where exact dimensions are required, such as in electronics manufacturing and aerospace.

Efficiency: Automatic cutting machines can work continuously and at a much faster pace than manual cutting methods. They can significantly increase production rates, reduce labor costs, and improve overall productivity.

Safety: By minimizing human - machine interaction during the actual cutting process, they reduce the risk of accidents associated with manual cutting tools such as knives and saws.

In conclusion, automatic cutting machines have revolutionized the manufacturing and processing industries. Their diverse applications, advanced working principles, and numerous advantages make them an indispensable asset for businesses aiming to produce high - quality products efficiently and safely. As technology continues to advance, these machines will only become more sophisticated, further enhancing their capabilities and expanding their applications in various fields.

GET A QUOTE